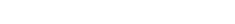

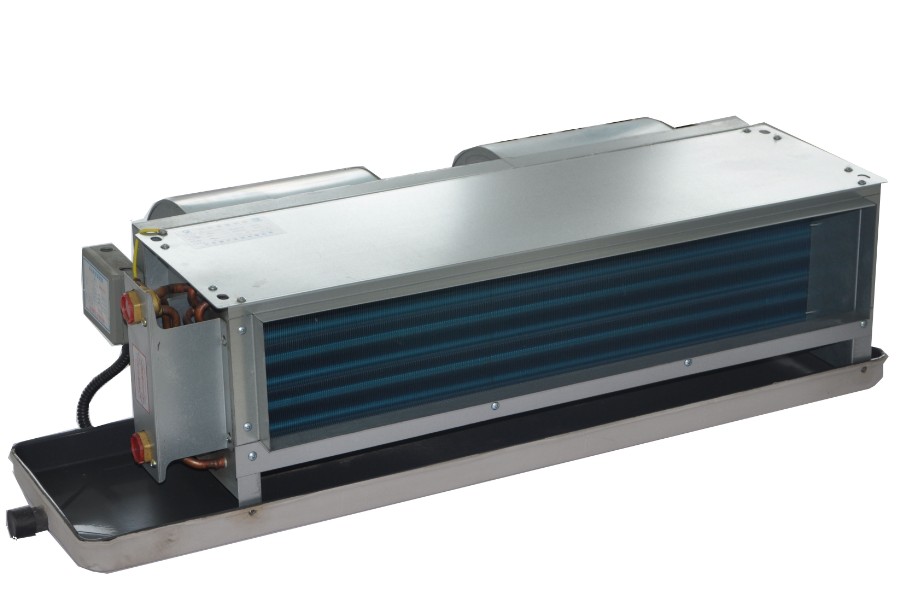

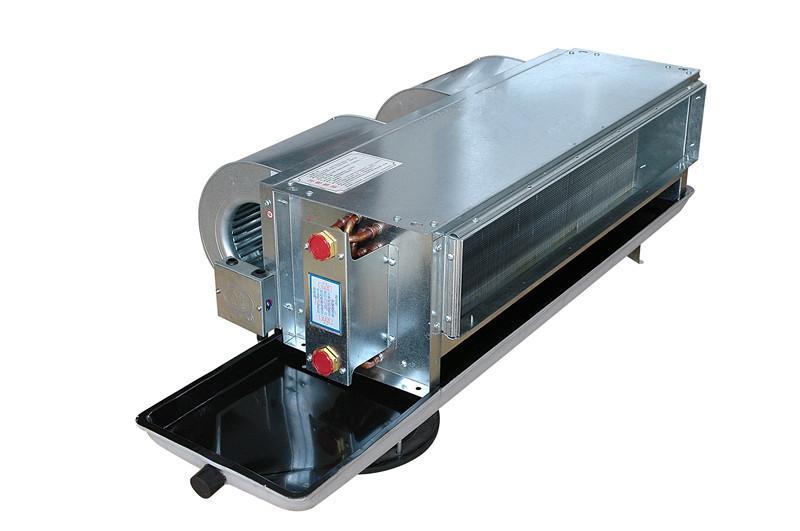

Duct Fan Coil Unit

PWFP series FCU are suitable for indoor unit of air conditioning system installed in hotels, residential buildings, office buildings, villas, radio stations, airports, subways and other applications.

1.Casing , high quality galvanized sheet with good corrosion resistance and rust resistance.

2.Fan ,silent metal blower, galvanized sheet, all fans through dynamic and static balance testing , stable operation, low noise, fan direct drive .

3.Motor ,Class E , three speeds , motor surface spray painting, good corrosion resistance, fully sealed, Permanently sealed and lubricated ball bearings .

4.Insulation ,The thermal conductivity of the material is 0.035w/m.k ,the flame retardancy reached the national B2 level. Operating temperature: - 50 ~ + 100 ℃.

5.Coil ,the copper tube is mechanically expanded to ensure close contact with the aluminum fins, high heat transfer efficiency. Strong corrosion resistance. All coils are qualified by 2.4 Mpa pressure leak detection.

6.Drain Pan ,One-step stamping, surface electrostatic powder coating , excellent anti-corrosion&anit-rust performance , beautiful appearance, durable, good insulation performance.

7.Motorized water valve and thermostat are optional.

PWFP series FCU are suitable for indoor unit of air conditioning system installed in hotels, residential buildings, office buildings, villas, radio stations, airports, subways and other applications. PWFP series fan coil units are advanced in design, complete in variety, superior performance, and better quality.

1. There are 9 models, suitable for different places. The air flow ranges from 320m ~ 2380m 3 / h, and the cooling capacity ranges from 1080W to 15480w,. All kinds of models are available with medium ESP and high ESP.

2. Power world FCU nominal air flow, ESP, sound level and performance are better than the national standard request .

3. With variable load, strong adaptability, flexible configuration of motorized water valve, thermostat and other building management system.

4. Beautiful appearance, delicate structure, durable. It use galvanized steel plate structure, equipped with front curved blade centrifugal double inlet silent metal fan, PSC motor and bearing without oil supplement. The fan has been strictly adjusted for dynamic and static balance, with stable operation, low noise, power saving and long service life, and normal operation can reach more than 10 years, so it is convenient for maintenance.

5. The coil is made of high-quality seamless copper tube and aluminum fin by mechanical expansion, secondary flanging and other strict processes. The double-sided high-efficiency tube fin heat exchanger coil with slits is used. All the products have passed the strict leakage detection of 2.4Mpa pressure, and the quality is guaranteed.

6. The coil can be easily disassembled to facilitate cleaning and maintenance. Coil inlet and outlet pipe installation can easily exchange the left and right direction. All the condensing water trays of the unit are extended type, which can ensure that the condensing water without insulation of the electric valve of the connected chilled water pipeline falls smoothly into the drain pan to prevent the condensation leakage .

7. The standard 2 pipe fan coil unit use 3-row coil , and the 4 pipe FCU adopts 4-row (3-row cooling and 1-row heating), which can be flexibly configured according to the customer's requirements.

8. Air return plenums is optional.

1. There are 9 models, suitable for different places. The air flow ranges from 320m ~ 2380m 3 / h, and the cooling capacity ranges from 1080W to 15480w,. All kinds of models are available with medium ESP and high ESP.

2. Power world FCU nominal air flow, ESP, sound level and performance are better than the national standard request .

3. With variable load, strong adaptability, flexible configuration of motorized water valve, thermostat and other building management system.

4. Beautiful appearance, delicate structure, durable. It use galvanized steel plate structure, equipped with front curved blade centrifugal double inlet silent metal fan, PSC motor and bearing without oil supplement. The fan has been strictly adjusted for dynamic and static balance, with stable operation, low noise, power saving and long service life, and normal operation can reach more than 10 years, so it is convenient for maintenance.

5. The coil is made of high-quality seamless copper tube and aluminum fin by mechanical expansion, secondary flanging and other strict processes. The double-sided high-efficiency tube fin heat exchanger coil with slits is used. All the products have passed the strict leakage detection of 2.4Mpa pressure, and the quality is guaranteed.

6. The coil can be easily disassembled to facilitate cleaning and maintenance. Coil inlet and outlet pipe installation can easily exchange the left and right direction. All the condensing water trays of the unit are extended type, which can ensure that the condensing water without insulation of the electric valve of the connected chilled water pipeline falls smoothly into the drain pan to prevent the condensation leakage .

7. The standard 2 pipe fan coil unit use 3-row coil , and the 4 pipe FCU adopts 4-row (3-row cooling and 1-row heating), which can be flexibly configured according to the customer's requirements.

8. Air return plenums is optional.

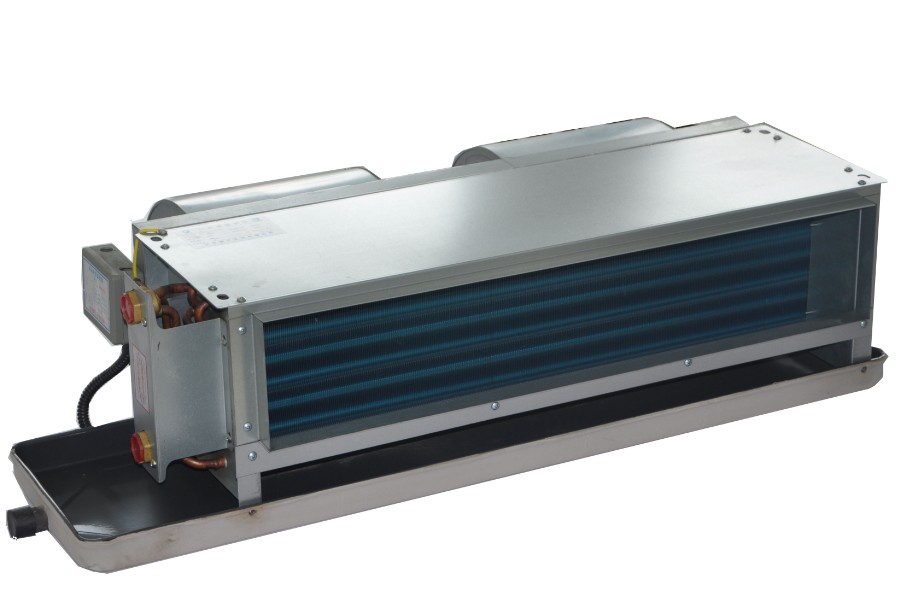

Ceiling concealed duct FCU ,2 pipes , 3 rows coill,with air return plenum

| Model PWFP- | 34WA | 51WA | 68WA | 85WA | 102WA | 136WA | 170WA | 204WA | 238WA | 250WA | ||

| Air Flow m3/h | H | 340 | 510 | 680 | 850 | 1020 | 1360 | 1700 | 2040 | 2380 | 2500 | |

| M | 260 | 380 | 510 | 640 | 770 | 1020 | 1280 | 1530 | 1790 | 1880 | ||

| L | 170 | 260 | 340 | 430 | 510 | 680 | 850 | 1020 | 1190 | 1250 | ||

| Cooling Capacity W | H | 2150 | 3220 | 4300 | 5380 | 6380 | 8610 | 10690 | 12320 | 14260 | 15480 | |

| M | 1640 | 2410 | 3230 | 4050 | 4870 | 6450 | 8110 | 9650 | 11350 | 11910 | ||

| L | 1080 | 1650 | 2150 | 2720 | 3210 | 4300 | 5380 | 6450 | 7530 | 7920 | ||

| Heating Capacity W | H | 3080 | 4570 | 6130 | 7660 | 9190 | 11890 | 14860 | 17260 | 21320 | 22580 | |

| M | 2380 | 3410 | 4570 | 5750 | 6960 | 9030 | 11410 | 13890 | 16180 | 19590 | ||

| L | 1540 | 2350 | 3050 | 3890 | 4580 | 6130 | 7790 | 9290 | 10890 | 12350 | ||

| Electric heater(Optional) | Type | PTC electric heater | ||||||||||

| W | 1000 | 1000 | 1500 | 2000 | 3000 | 3000 | 4500 | 4500 | 5000 | 6000 | ||

| Coil Heat Exchanger | Water Flow | m3/h | 0.37 | 0.55 | 0.74 | 0.93 | 1.1 | 1.48 | 1.84 | 2.12 | 2.46 | 2,67 |

| WPD | kPa | 9 | 12 | 17 | 22 | 31 | 14 | 18 | 24 | 32 | 35 | |

| Working Pressure | 1.6 MPa | |||||||||||

| Power Consumption (W) | 0Pa | 36 | 46 | 54 | 64 | 91 | 109 | 136 | 201 | 217 | 233 | |

| 30Pa | 39 | 54 | 72 | 87 | 109 | 136 | 161 | 217 | 233 | 252 | ||

| 50Pa | 46 | 64 | 90 | 109 | 136 | 161 | 187 | 233 | 252 | 276 | ||

| Sound Level dB(A) | 0Pa | 34 | 36 | 37 | 38 | 40 | 43 | 44 | 47 | 50 | 51 | |

| 30Pa | 36 | 37 | 38 | 40 | 42 | 44 | 45 | 49 | 52 | 53 | ||

| 50Pa | 41 | 43 | 45 | 46 | 47 | 48 | 49 | 51 | 54 | 55 | ||

| Blower | Type | DIDW centrifugal forward fan | ||||||||||

| Qty | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 4 | 4 | ||

| Motor | Type | Permanent-capacitor three speeds motor | ||||||||||

| Power Supply | 220V/1phase/50HZ | |||||||||||

| Qty | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | ||

| Water Inlet/Outlet | 3/4' female thread | |||||||||||

| Drain Pipe | 3/4' female thread | |||||||||||

| Weight | kg | 30 | 30 | 30 | 30 | 40 | 40 | 40 | 40 | 50 | 50 | |

Remark :

1.Cooling testing condition return air dry ball/wet ball temperature 27℃/19.5℃ ,chilled water inlet temperature 7℃ , chilled water outlet temperature 12 ℃

2.Heating testing condition return air dry ball temperature 21 ℃ ,hot water inlet temperature 60℃,hot water outlet tempeature 50 ℃

inquiry

Leave your phone number in your mailbox, we will call you within 24 hours